Engineering Services

Matric employs a full-time in-house engineering staff to assist you with your project, whether you need a simple PCB layout or a complete turnkey design. From initial discussions through final product validation, we work with you to take your product to market.

NOTE: Dynamic Manufacturing and Matric Limited’s AS9100D and Matric Limited's ISO 13485:2016 certifications apply to the manufacturing and aftermarket servicing of electronic, electromechanical and cable assemblies. Design and engineering services are not certified to these quality standards.

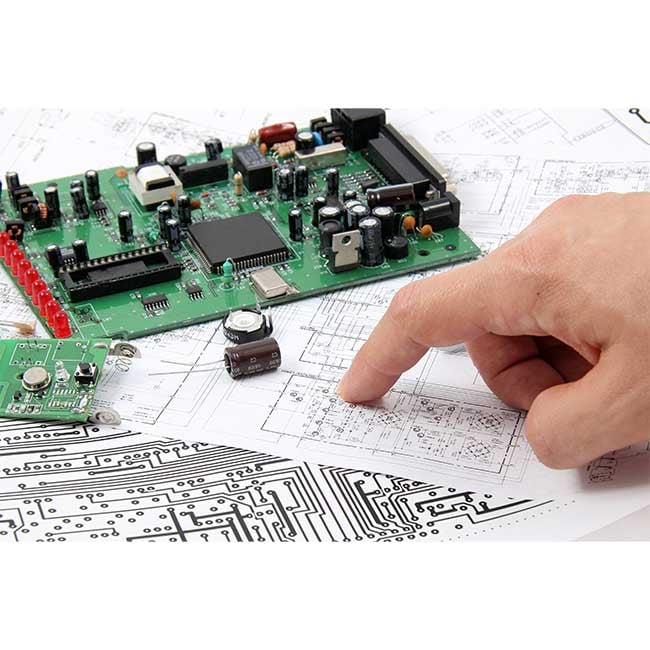

PCB LAYOUT & DESIGN

A printed circuit board (PCB) can be an asset or a liability for an electronic product. For more than 35 years, we have designed PCBs for various challenging applications. Our designers are IPC-certified and skillful craftsmen who will work with you to design a quality PCB that meets all your requirements.

CAPABILITIES:

- High-Speed Digital Designs to GHZ+ on FR4 & High-Performance Materials

- Low-Level Analog, RF, LVDS, GTL+, PECL

- DDR/DDR2 & 3, Memory, DVI, Ethernet, USB2, PCIX, PCI

EMC/EMI SIGNAL INTEGRITY ANALYSIS:

- Termination & Topology Strategies

- Stack-Up, Impedance & Analysis

CIRCUIT BOARD DESIGN:

- Complete Traditional Printed Circuit Boards - 1 to 30 layers

- Micro-BGA, Micro-Vias, HDI, Impedance Control

- Pre-Layout Thermal Planning

- Low-Loss Materials, Metal Cores, Heat Plates

BOARD FABRICATION:

- Pre-Fabrication IPC Netlist

- Verification of Gerbers

- IPC Netlist Board Conformance

Testing - Schematic Printed Circuit Board Layout Design

ASSEMBLY & PROTOTYPING:

- Component Procurement

- Turnkey Assembly

- Cabling, System Board

- Interconnect

PERMISSIBLE AREA EQUIPMENT:

- Mining, Oil & Gas Applications

- Explosion Proof Designs

- Intrinsically Safe Designs

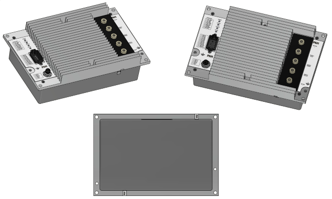

MECHANICAL DESIGN

Your systems have mounting and volume constraints. We can help you meet those needs and package your PCB efficiently in an appropriate enclosure. Machined, fabricated, or molded can be provided. CAD 3D modeling of PCBs, components, enclosures, and mounting will verify efficient manufacturing and fitment for your application before integration occurs.

CAPABILITIES:

- Conceptual Designs, Proposals, Proof of Concept

- Industrial Design

- Controls & Panel Design using Silicone Keypads/Sealed

- Key Switch Technology

- Sheet Metal Enclosure Product Design

- Vendor Selection Assistance for Prototype Tooling

- Reverse Engineering

- Legacy Conversions - 2D Drawings & Modeling into 3D Formats

PRIMARY SOFTWARE PLATFORMS:

- AutoCAD Inventor

- SolidWorks

ELECTROMECHANICAL PRODUCT DESIGN:

- Conceptual Development

- Detailed Design

- Hardware

- Software

- Enclosure Solutions

- Engineering

- Prototyping

- Product Testing

- Manufacturing

- Computer-Aided Drafting

- General Solid Modeling

- Sheet Metal Modeling

- Detailing & Drafting

- Complex Assembly Mgmt. Complex Surfaces (Class A)

- Wire & Pipe Routing

- Digital Renderings

HARDWARE DESIGN

Our design services cover the full capabilities required to produce a complete PCB or packaged product. Circuit design services include analog, digital, power, and RF integration. Our Hardware Design team can work seamlessly with in-house manufacturing and software developers or provide documentation for 3rd party integrators.

CAPABILITIES:

- Project & Risk Management

- Contingency & Technology Planning

- High-Level System Architecture

- Functional & Technical Specifications

- Advanced Electronic Circuit Design

- Mechanical/Packaging Design

- Industrial Design/3D Modeling

- Rapid Prototyping

- Simulation/Analysis

- Digital/Analog/Thermal/FEA

- Build & Test System Design

- Application Development

- Prototype Development

- Assembly

- Design Validation

- Environmental Testing

- Mechanical & Electrical

- Manufacturing Documentation

- ICT/FT & Manufacturing Management

AREAS OF EXPERTISE:

- Wireless Intelligent Design/Antennas

- Extensive RF/RFID Design/Bluetooth

- 8/16/32/64 Bit uC

- High-Speed Digital

- Low-Level Analog

- Signal Conditioning

- DC/DC Power Conversion

- Battery Management

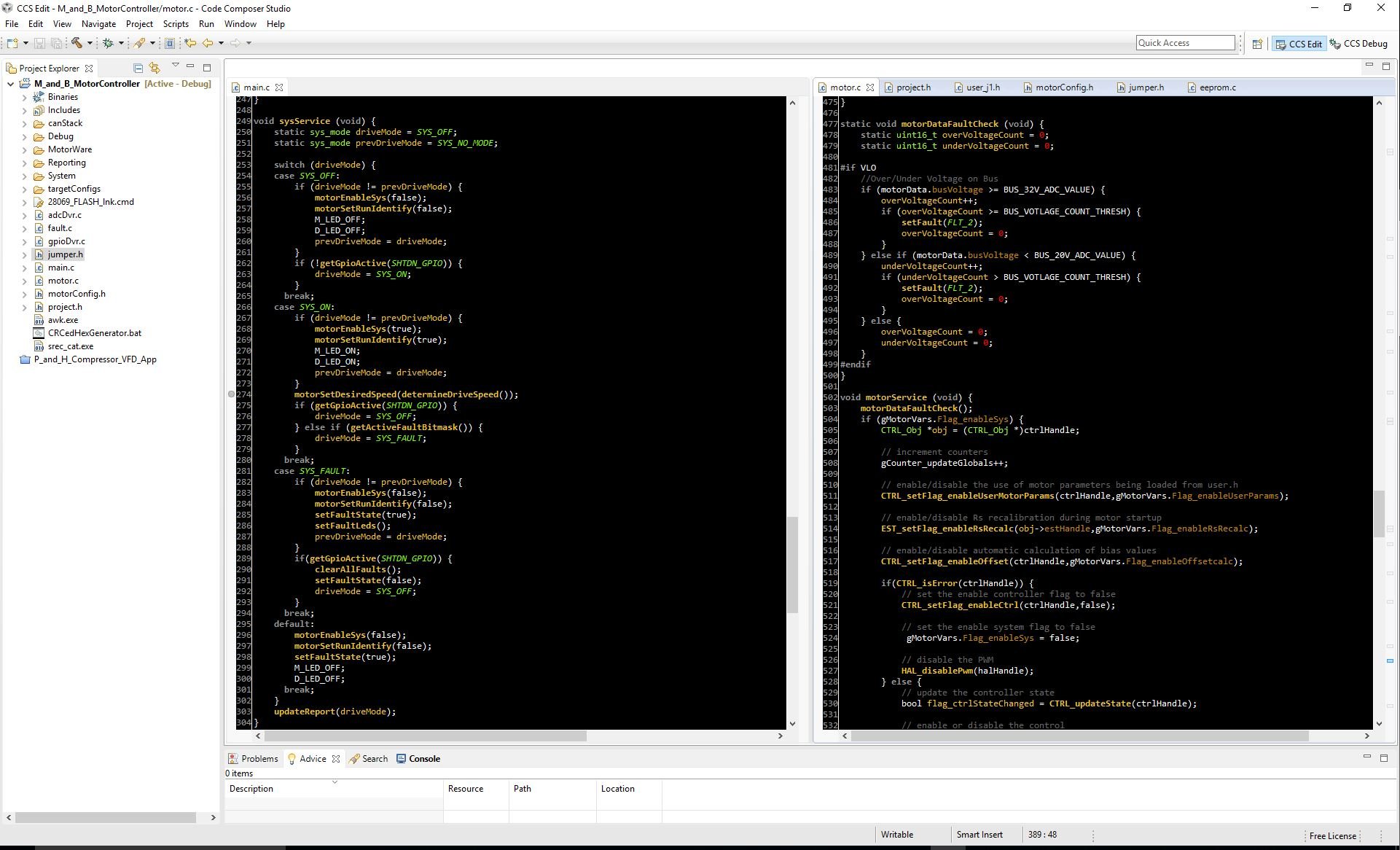

SOFTWARE DESIGN

Our engineers are well-versed in the issues of real-time software design. Applications that involve data integrity, deterministic machine control, multitasking, distributed control and communication, and proportional integral differential (PID) control are common ground for our engineering team.

EMBEDDED SOFTWARE:

- C/C++ & Assembly

- 8/16/32-Bit Embedded Microcontrollers, Microchip, TI, Atmel, Freescale, 8051s & more

- Embedded Microprocessors - x86, PowerPC, ARM

- Communication Devices

- Control Applications

- Instrumentation

SOFTWARE LANGUAGES:

- C, C++, C#

- Visual Studio, .NET

- Visual BASIC

- Various Assemblers

OPERATING SYSTEMS:

- Windows 98/NT/2000/XP/Vista

- Linux - Embedded & Desktop/Server

TEST/MEASUREMENT LABVIEW APPLICATIONS:

- Integrating Data Acquisition Boards & Systems

PRIMARY SOFTWARE PLATFORM:

- Test Systems

- Control Applications

- Windows Device Drivers

PROTOCOLS:

- TCP/IP & Ethernet

- USB

- MODBUS, CAN

- Bluetooth, WiFi, Zigbee

TESTER DESIGN

Matric has in-line and MDA test capabilities for manufacturing your product. The quality of your product can improve when we include burn-in and/or full functional testing. Exercising your unit with real-life or simulated loads can provide confidence that the product will work in your end application.

Matric can deploy one of your testers with an established procedure or help to create a new tester and process from minimal information. Customer involvement is recommended and likely includes approval of test rigs and operations.

FUNCTIONAL TEST EQUIPMENT APPROACHES:

- Customer provides Matric full test rig and procedure to use on their product

- Customer provides tester specifications and IP for full test rig creation by Matric

- Customer provides target assembly I/O and functional definition for Matric to create a tester

- Customer provides schematic, PCBA sample, or turnkey sample for Matric to create a tester

- Customer is requested to approve test methods and test procedure

CERTIFICATIONS

Certifications standardize our processes internally and equalize us with competing contract manufacturers. Each certification we achieve drives and maintains continual improvement.

- ITAR Compliant

- RoHS Compliant

- ISO | IEC 80079-34

- HUBZone Certified

VALUE-ADDED SERVICES

Although we offer quick turn board assemblies, we are a full-service contract manufacturer providing a menu of value-added options. With over 50 years of experience in this industry, we are your one-stop shop.