Matric Group Services

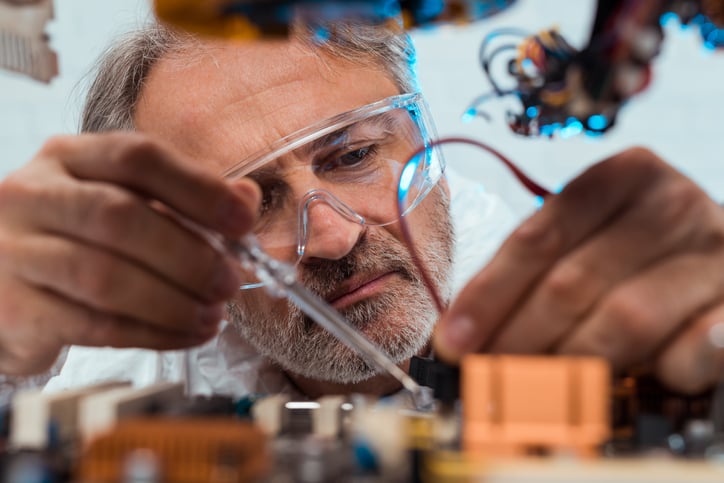

PCB Engineering Services

Matric employs a full-time in-house engineering staff to assist you with your project, whether you need a simple PCB layout or a complete turnkey design. From initial discussions through final product validation, we work with you to take your product to market.

From PCB Layout & Design, Mechanical Design, Hardware Design, Software Design, & Tester Design, our advanced engineering services cover a vast range of capabilities.

PCB ENGINEERING SERVICES: 4 QUALITIES TO LOOK FOR

When you’re looking for a PCB engineering services provider, there are, of course, multiple things to consider. “Will they be able to meet my specific needs?” is likely your first and foremost concern.

PCB Assembly Services

We specialize in low-to-high volume, complex assemblies that other contract manufacturers can't handle. Our fully automatic SMT lines, semi-automatic THT equipment, and our experienced hand assembly team will benefit your bottom line.

From Surface Mount Technology, Through-Hole Technology, Inspection & Testing, Equipment, and PCB Panel & Component Specifications, our printed circuit board (PCB) assemblies can be designed for various challenging applications

IPC CLASS DEFINITIONS FOR CLASS 1, 2, & 3 ELECTRONICS

In electronics manufacturing, printed circuit boards are separated into three categories: 1, 2, and 3. The categories reflect the level of quality of each circuit board type, from lowest (Class 1 standards) to highest (Class 3 standards). This classification system was developed and is monitored by IPC under the IPC-6011 standard.

Cable & Harness Assembly Services

We specialize in harsh-environment cables and harnesses. We design, test, and manufacture quality cable assemblies from micro push-pull connectors to harnesses, to interconnects and complex assemblies.

Our capabilities cover everything from harsh environment cable, custom cable & wire harnesses, custom overmolding, panel/box wiring, custom mold design, and more.

WHAT TO KNOW ABOUT ELECTRONIC CABLE & HARNESS ASSEMBLY

When it comes to making a custom electronic cable and harness assembly, the little details matter. A faulty wire or a bad connection could ruin an expensive piece of equipment and slow down manufacturing processes.

A GUIDE TO REVERSE POLARITY PROTECTION IN PCB DESIGN

When user safety depends on equipment functioning reliably -- as with many medical devices and handheld mining equipment, for example -- electronic components must be trustworthy.

Electromechanical Assembly Services

Our final assembly team is dedicated to seamlessly integrating PCBs into box builds, enclosures, and other projects, no matter how simple or complex they may be. Rest assured that you can rely on us for successful integration.

Our capabilities include box build, final assembly, custom packaging, encapsulation capabilities, intrinsically safe assembly, and explosion-proof assembly. We follow a rigorous inspection and testing process.

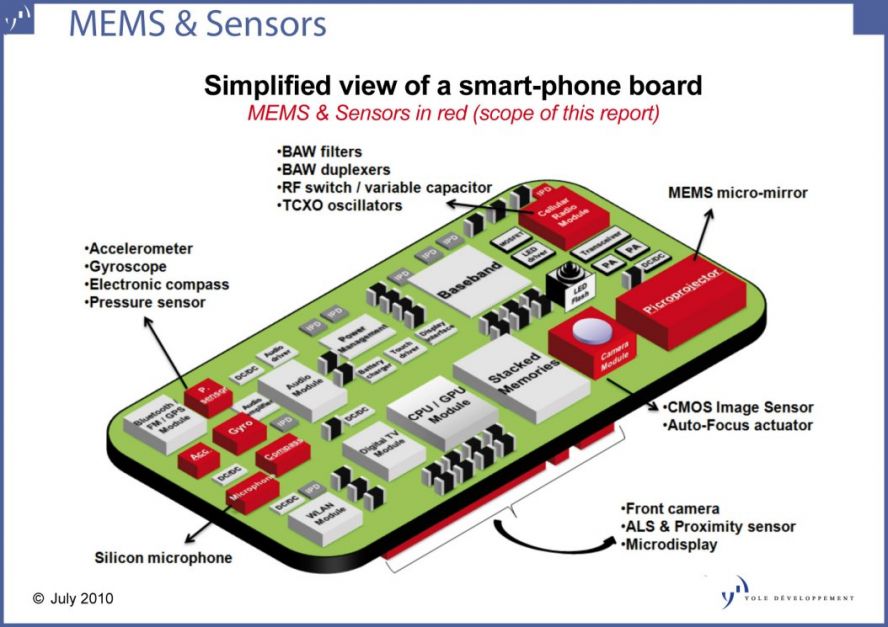

MEMS DESIGN GUIDE FOR PCB ELECTROMECHANICAL ASSEMBLIES

Microelectromechanical systems, or MEMS, are the microscopic building blocks of current electronics. Look no further than the smartphone in your pocket -- these tiny devices make up many of the sensors in our phones that collect data like motion and image stabilization.

CAPABILITIES OF AN ELECTRONIC MANUFACTURING SERVICES COMPANY

Do you work for an original equipment manufacturer or OEM? Chances are you’ve crossed paths with a project requiring an electronic manufacturing services company.

Aftermarket Services

Our commitment to customer satisfaction continues after products are delivered. We offer upgrades, calibration, and repair services to maintain the proper operation of your products. Our services also include manufactured elsewhere and legacy products that require sustaining engineering.

We have the edge with unequaled experience, expertise, and technology. We have the know-how to service it properly. Our experiences support industrial and consumer products, and our skilled technicians and state-of-the-art equipment are at your disposal.

HOW AFTERMARKET ELECTRONICS REMANUFACTURING BOOSTS THE ENERGY INDUSTRY

Massive amounts of money are at play when it comes to power distribution electronics. The electronic product development life cycle frequently sparks frustration among OEMs in this industry because parts steadily wear out and require attention to keep critical infrastructure operating.

ELECTRONICS AFTERMARKET SERVICES: THE A TO Z GUIDE

You buy your electronic components, your machines are up and running, customers are happy, your workers are happy -- everything is good. Invoice paid, accounts receivable piling up. Paradise.

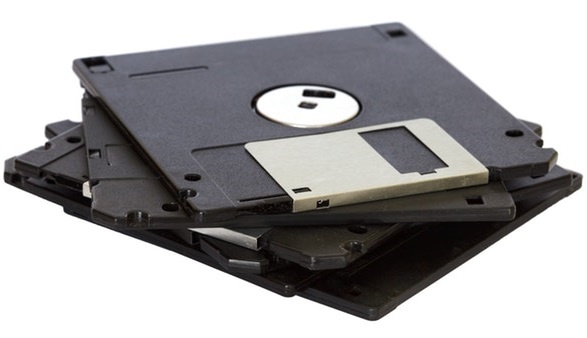

Obsolescent Management

Original equipment manufacturers (OEMs) deal with outdated parts all the time. Failure to keep up with the latest components can doom the life cycle of your product.

Limited availability, dubious component quality, and conflict mineral laws are common causes of you and your manufacturer’s headaches when it comes to sourcing parts.

That’s why we use the best obsolescence management software in the industry — SiliconExpert. SiliconExpert functions as a database of over 250 million components from thousands of suppliers

BASICS OF OBSOLESCENCE MANAGEMENT FOR ELECTRONICS

The most painful part of developing with electronics is knowing your success is fleeting. Eventually, all parts must die, or at least fade away into irrelevance. But there’s something you can do about it. Obsolescence management can guide you through this difficult process.